More than 80% of the graphite used in the power battery is artificial graphite. A large number of studies show that the structure of the negative carbon material in the power battery after scrapping is basically unchanged, which has the basis of reuse. After preliminary acid leaching, the fixed carbon content is increased to more than 98.5%. The regenerated graphite composites can be prepared by modifying the surface by low temperature oxidation and coating.

Taking the typical VDA size ISP2714897-50Ah cell as an example, the total carbon content is about 20%. The formation of carbon mainly includes negative graphite, conductive agent (positive and negative electrode) and pyrolytic hard carbon (diaphragm cracking product) and other materials. If the toner is not properly treated, a large amount of hazardous waste will be generated in the production process.

In this project, the primary classification is made according to the source form of waste carbon powder, and the step recycling strategy can better improve the consistency of recycled negative electrode materials and the added value of products. The brief description is as follows:

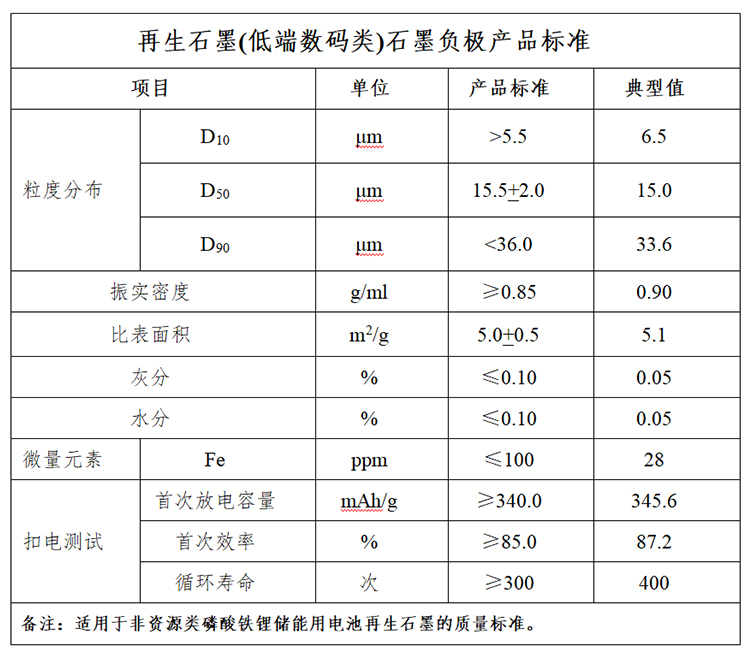

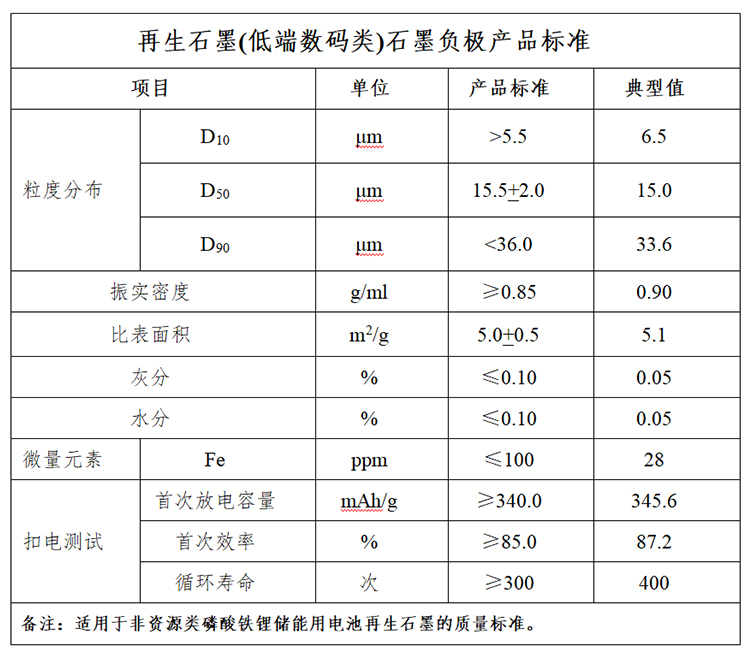

(1) For waste batteries or electrode sheets with unknown status or made from graphite electrode recycled materials, the product standard of this kind of recycled graphite is mainly considered in low-end digital application scenarios, and its indicators are as follows:

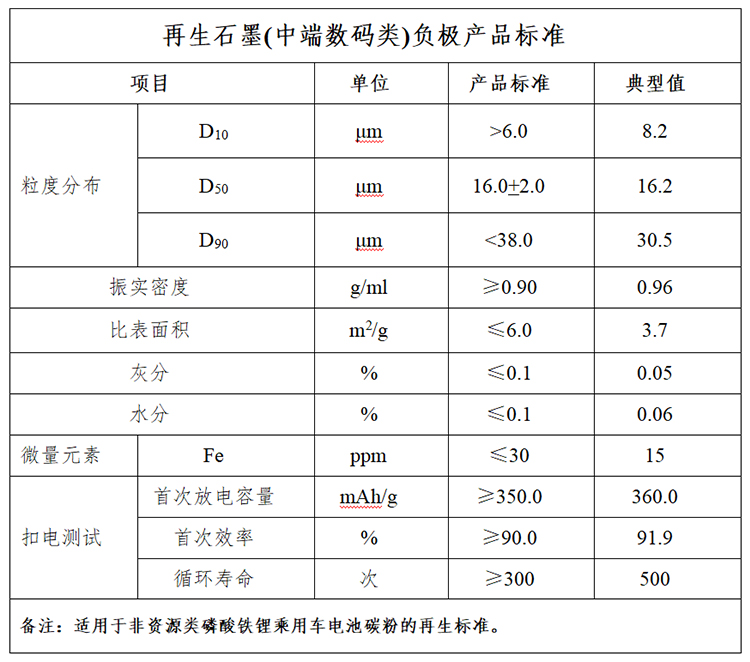

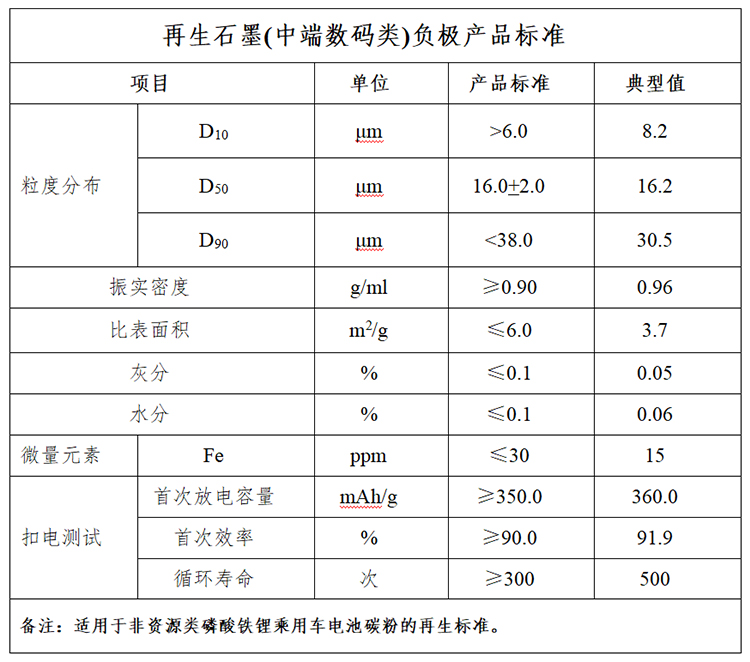

(2) For the lithium iron phosphate energy storage battery or electrode sheet with the negative electrode made of petroleum coke, the target of graphite regeneration should be mainly considered in medium and low-end digital application scenarios, and the indicators are as follows:

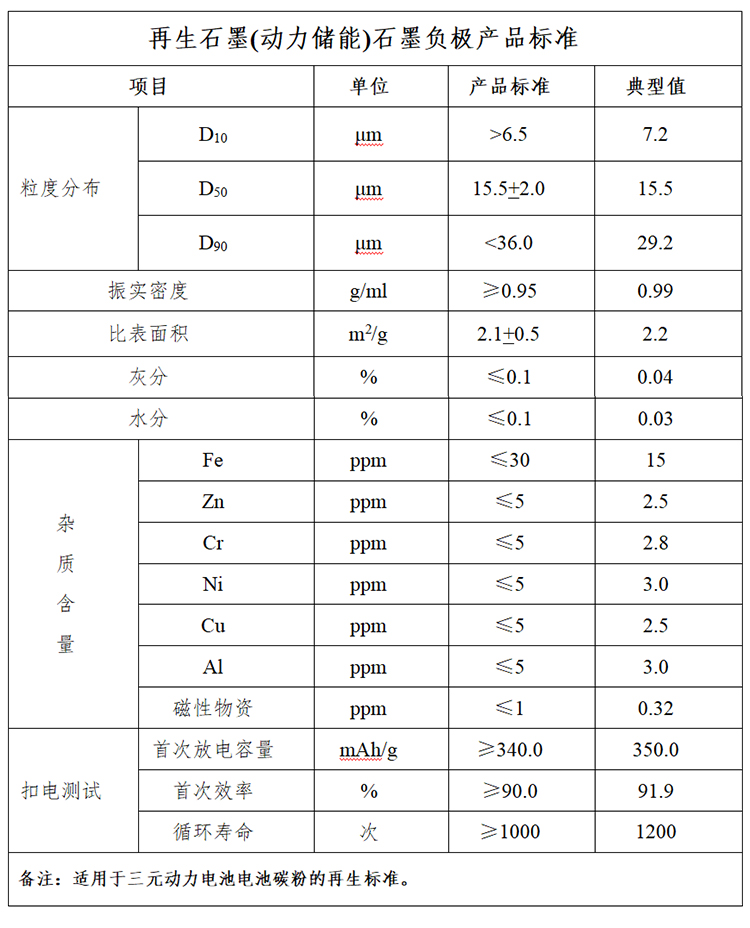

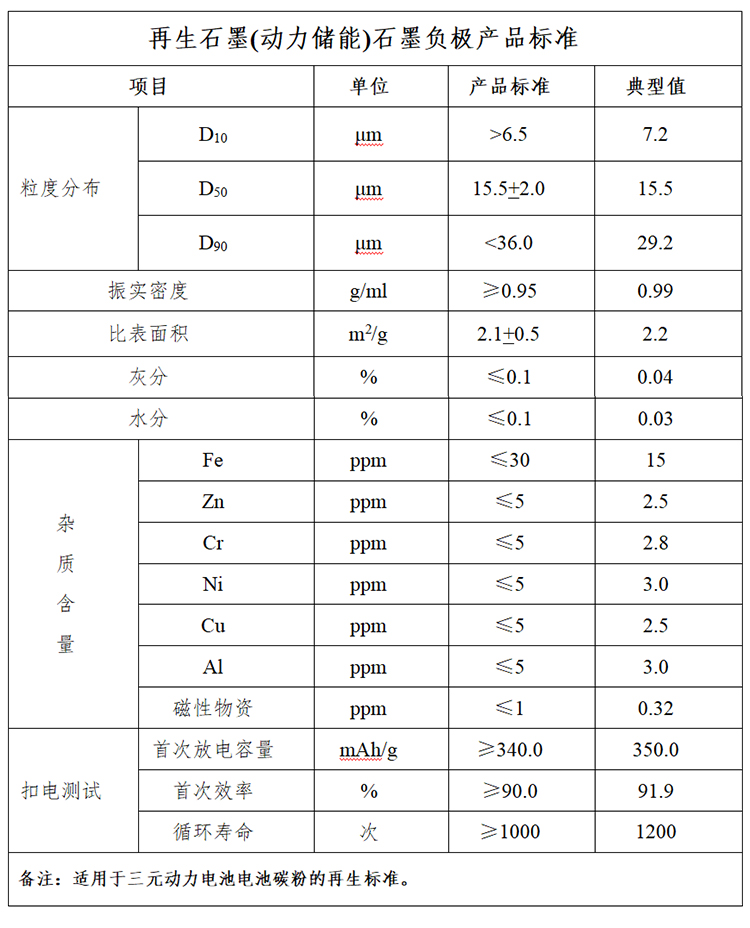

(3) For the three-way power battery or pole piece made of needle coke for the negative electrode, the target of regeneration is mainly based on the standard of energy storage materials, and the relevant indicators are as follows:

More than 80% of the graphite used in the power battery is artificial graphite. A large number of studies show that the structure of the negative carbon material in the power battery after scrapping is basically unchanged, which has the basis of reuse. After preliminary acid leaching, the fixed carbon content is increased to more than 98.5%. The regenerated graphite composites can be prepared by modifying the surface by low temperature oxidation and coating.

Taking the typical VDA size ISP2714897-50Ah cell as an example, the total carbon content is about 20%. The formation of carbon mainly includes negative graphite, conductive agent (positive and negative electrode) and pyrolytic hard carbon (diaphragm cracking product) and other materials. If the toner is not properly treated, a large amount of hazardous waste will be generated in the production process.

In this project, the primary classification is made according to the source form of waste carbon powder, and the step recycling strategy can better improve the consistency of recycled negative electrode materials and the added value of products. The brief description is as follows:

(1) For waste batteries or electrode sheets with unknown status or made from graphite electrode recycled materials, the product standard of this kind of recycled graphite is mainly considered in low-end digital application scenarios, and its indicators are as follows:

(2) For the lithium iron phosphate energy storage battery or electrode sheet with the negative electrode made of petroleum coke, the target of graphite regeneration should be mainly considered in medium and low-end digital application scenarios, and the indicators are as follows:

(3) For the three-way power battery or pole piece made of needle coke for the negative electrode, the target of regeneration is mainly based on the standard of energy storage materials, and the relevant indicators are as follows: